Batang Bor untuk Pemesinan Presisi Tinggi dan Komponen Kecil

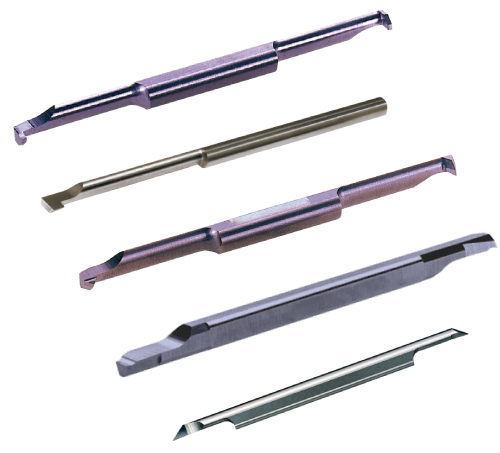

MIKRO-MINI KEMBAR

Ideal for small-diameter boring of general and stainless steel.

Fitur

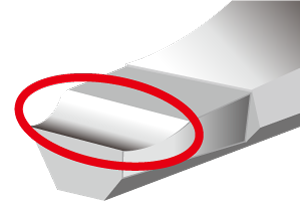

Double Ended Cutting Edges

A cutting edge on each end provides reduced tooling costs.

Wide Range Available

The multi functionality of the Micro-Mini Twin enables a wide application range that covers boring, grooving and threading and is available with or without a chipbreaker.

・Boring

Minimum Cutting Diameter : φ2.2mm~

RE : 0.05, 0.1, 0.15, 0.2

・Grooving

Minimum Cutting Diameter : φ3mm~

・Threading

Minimum Cutting Diameter : φ3mm~

・Copying

Minimum Cutting Diameter : φ3.5mm~

Available With or Without a Chip Breaker

With Chip Breaker

The wide chip breaker aids in reducing cutting resistance.

With Out Chip Breaker

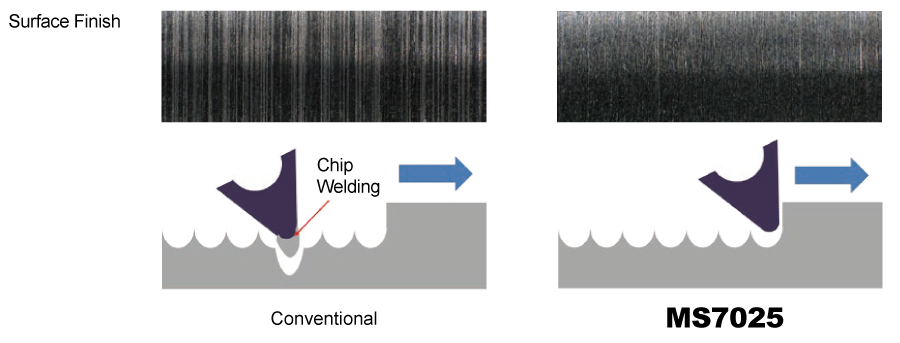

Polished rake face to prevent chip welding.

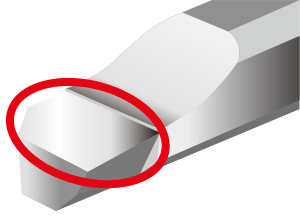

Kinerja Pemotongan

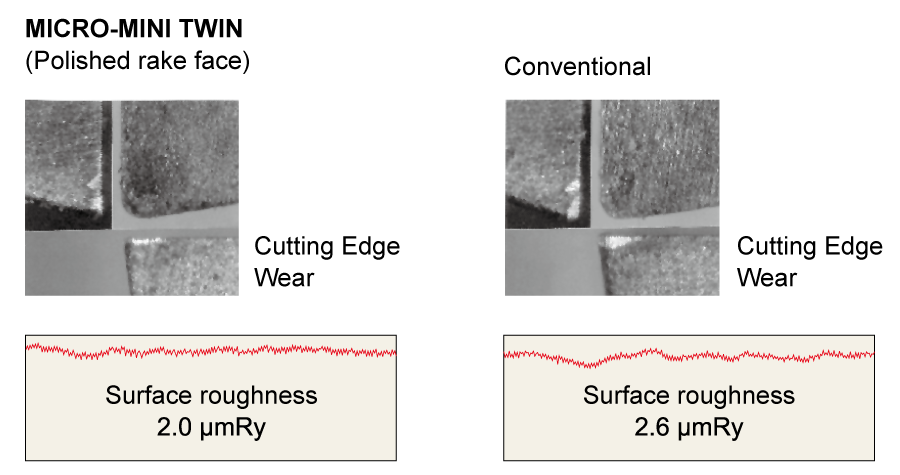

Polished Rake Face

Machining of Stainless Steel

The polished rake face prevents chip welding and provides an excellent surface finish.

Workpiece Material : SUS304 Tool : CB05RS,VP15TF

Cutting Speed : vc=100m/min Feed per Rev. : fr=0.02mm/rev

Cutting Depth : ap = 0.1 mm Cutting Mode : Wet Cutting

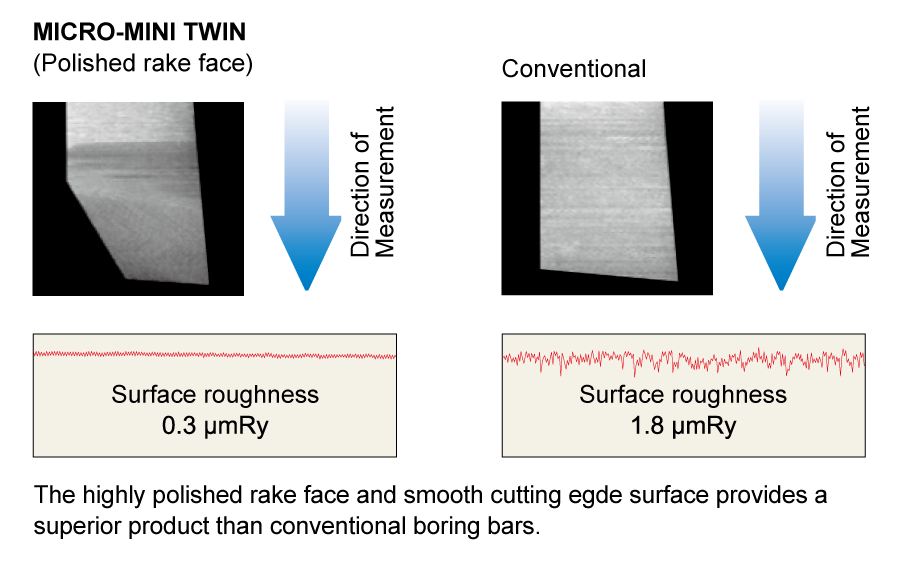

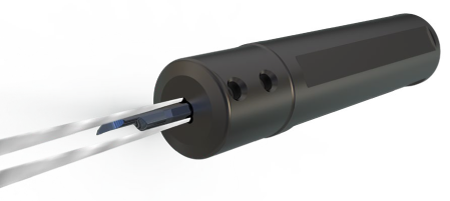

Sleeve

A sleeve specially designed the MICRO-MINI TWIN for optimum use on Swiss-Type lathes.

・The overall length is optimized for each machine manufacturers model, therefore no need to reduce the length of the tool.

・Intermediate diameters, such as the 2.5 mm I.D., 3.5 mm, 4.5 mm, have also been added. Not only Micro-Mini Twin but also small diameter boring bars can also be mounted.

・Four notches for clamping also allows for side fixation.

With Coolant Hole

Sleeve inner diameter : 3 mm-12 mm

Functional length 67 mm, 80 mm, 85 mm, 110 mm, 115 mm

Without Coolant Hole

Sleeve inner diameter : 2 mm-12 mm

Functional length 67 mm,80 mm, 85 mm, 110 mm, 135 mm

PVD Coated Grades for High Precision and Small Parts Machining MS9025

Effectively reduces notch wear whilst also providing fracture resistance.

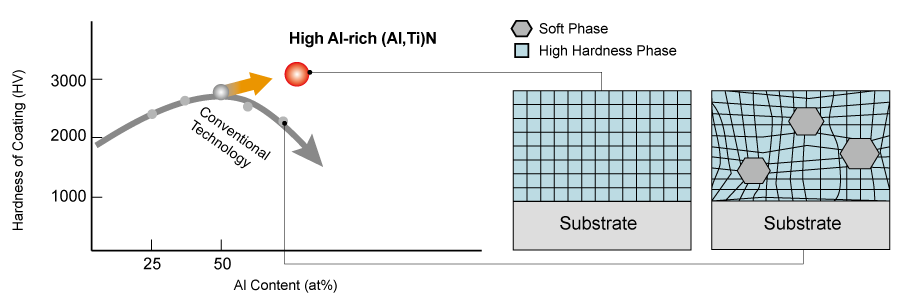

High Al-rich (Al, Ti)N Single Layer Coating Technology

High Al and Conventional Coating Comparison

The high Al-rich (Al,Ti)N single layer coating provides stabilisation of the high hardness phase and succeeds in dramatically improving wear, crater and welding resistance.

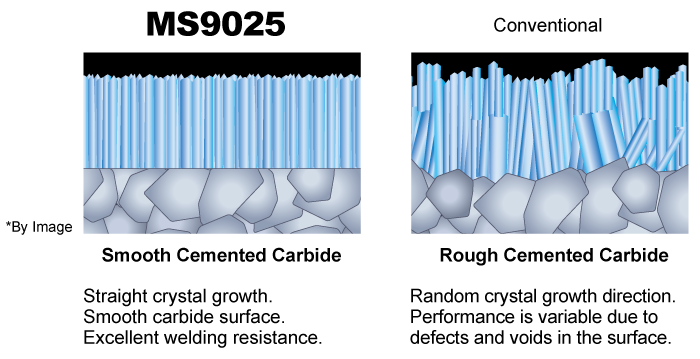

Permukaan Lapisan Halus

The even surface of the coating has been achieved by first making the the carbide substrate smooth, then by promoting straight growth of the coating crystals.

This leads to excellent welding resistance.

PVD Coated Grades for High Precision and Small Parts Machining MS7025

Peningkatan pengelasan dan ketahanan aus secara drastis dalam pemesinan umpan rendah dengan lapisan nano-multilayer yang lebih presisi

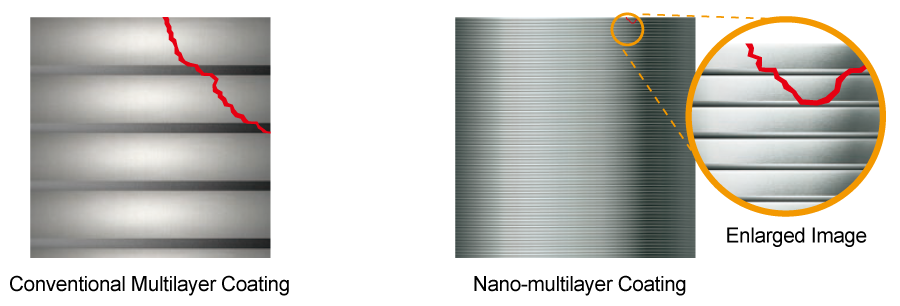

Pelapisan Nano-Multilayer

Dengan menggabungkan lapisan pelumasan tinggi dengan ketahanan pengelasan yang sangat baik, dan lapisan kekerasan tinggi dengan ketahanan aus yang lebih besar yang menekan kemajuan keausan pada tingkat nano, kerusakan film berkurang secara signifikan dan ketahanan pengelasan dan keausan meningkat secara dramatis.

Efek Lapisan Pelumasan Tinggi

Lapisan pelumasan tingkat nano yang tinggi menekan terbentuknya tepi tajam yang disebabkan oleh pengelasan chip yang cenderung terjadi pada pemesinan umpan rendah dan sebagai tambahan mengurangi permukaan mesin.

Konsultasi teknis dari sini

Formulir kontak

Jepang

Jepang Amerika Serikat

Amerika Serikat Meksiko

Meksiko Brazil

Brazil Uni Eropa

Uni Eropa Inggris Raya

Inggris Raya Jerman

Jerman Spanyol

Spanyol Perancis

Perancis Italia

Italia Polandia

Polandia Turki

Turki Republik Ceko

Republik Ceko Cina

Cina Asia Pasifik

Asia Pasifik Vietnam

Vietnam Indonesia

Indonesia India

India